Unlocking the Advantages of Best Circuit Board Fabrication for Diverse Product Applications

Circuit Board Fabrication plays a pivotal role in the electronics industry, supporting a wide array of applications that drive innovation across various sectors. According to a recent market report from Research and Markets, the global printed circuit board (PCB) market is projected to reach $82.37 billion by 2026, growing at a CAGR of 4.98% from 2021. As digital devices become more sophisticated, the demand for high-quality circuit boards capable of withstanding complex functionalities is paramount. Countries with top-ranking manufacturing facilities, particularly in Asia, are at the forefront of this trend, providing advanced solutions that optimize performance and enhance reliability. This blog will explore the advantages of leveraging the best circuit board fabrication methods and their implications for diverse product applications, emphasizing how these capabilities can elevate technological advancements and meet rising consumer demands in a competitive landscape.

Circuit Board Fabrication plays a pivotal role in the electronics industry, supporting a wide array of applications that drive innovation across various sectors. According to a recent market report from Research and Markets, the global printed circuit board (PCB) market is projected to reach $82.37 billion by 2026, growing at a CAGR of 4.98% from 2021. As digital devices become more sophisticated, the demand for high-quality circuit boards capable of withstanding complex functionalities is paramount. Countries with top-ranking manufacturing facilities, particularly in Asia, are at the forefront of this trend, providing advanced solutions that optimize performance and enhance reliability. This blog will explore the advantages of leveraging the best circuit board fabrication methods and their implications for diverse product applications, emphasizing how these capabilities can elevate technological advancements and meet rising consumer demands in a competitive landscape.

The Role of Advanced Circuit Board Fabrication in High-Tech Product Development

The modern landscape of high-tech product development is heavily reliant on advanced circuit board fabrication techniques. These innovative processes enable the production of high-density interconnects, multilayer designs, and complex geometries that cater to the ever-evolving demands of technology. With industries ranging from telecommunications to medical devices relying on cutting-edge electronics, the role of advanced fabrication techniques has become pivotal. By leveraging state-of-the-art materials and precision manufacturing methods, firms can create circuit boards that not only meet strict performance specifications but also enhance product reliability and efficiency.

Moreover, the incorporation of advanced circuit board fabrication not only accelerates the design-to-market timeline but also facilitates the customization of products for diverse applications. Engineers can utilize rapid prototyping and scalable manufacturing solutions to iterate designs efficiently and accommodate specific operational requirements. This agility in production ensures that companies can respond to market trends and consumer needs with greater speed and flexibility, ultimately leading to more innovative and competitive products in the high-tech arena.

Unlocking the Advantages of Best Circuit Board Fabrication for Diverse Product Applications

This chart illustrates the benefits of advanced circuit board fabrication techniques in various high-tech product applications, reflecting the percentage improvement in efficiency, cost-effectiveness, and product quality.

Key Benefits of Custom Circuit Board Manufacturing for Industry-Specific Solutions

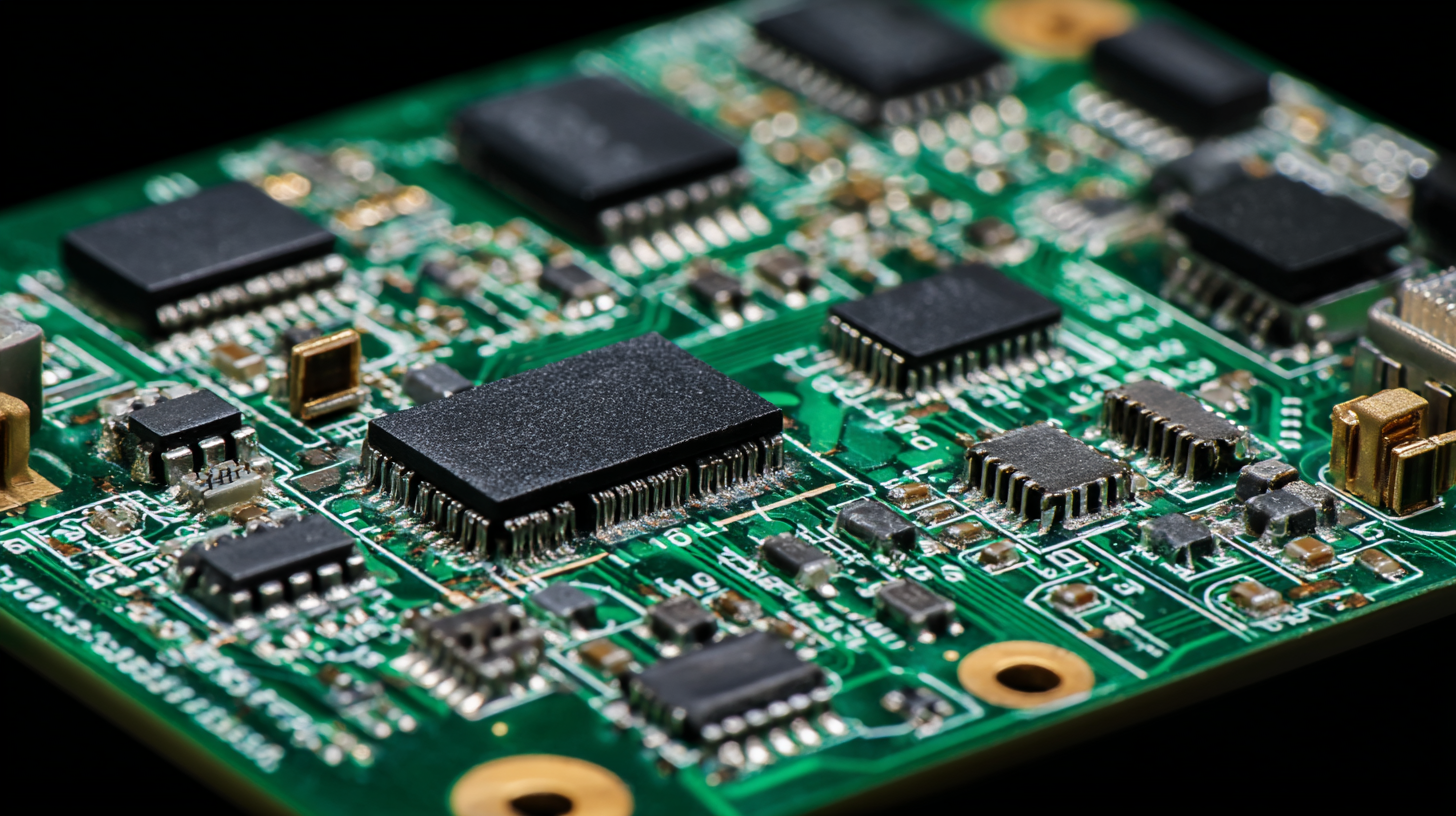

In today's fast-paced technological landscape, custom circuit board manufacturing plays a crucial role across various industries. The ability to design and fabricate circuit boards tailored to specific applications allows companies to enhance the performance and efficiency of their products. Whether in medical devices, automotive systems, or consumer electronics, custom circuit boards can meet unique challenges and requirements, leading to innovative solutions that drive market success.

One of the key benefits of this tailored approach is the optimization of functionality and reliability. By utilizing specialized materials and design techniques, manufacturers can create circuit boards that perform better under specific operational conditions. This is particularly important in high-stakes fields like aerospace and healthcare, where precision and durability are paramount. Moreover, custom circuit boards can streamline production processes, reduce waste, and lower costs, ultimately providing a competitive edge for businesses in diverse sectors. The adaptability of custom circuit boards ensures that companies can quickly respond to changing market demands while maintaining high standards of quality and performance.

Analyzing the Market Trends in Circuit Board Fabrication for Electronics

The circuit board fabrication market is witnessing significant growth, driven by the increasing demand across diverse applications such as automotive, consumer electronics, and telecommunications. According to recent market analysis, the global PCB assembly market is projected to reach substantial figures in 2032, with particular growth in sectors like industrial electronics and medical devices. The automotive PCB market alone is expected to expand from $9.15 billion in 2023 to $15.1 billion by 2032, showcasing a compound annual growth rate (CAGR) of 5.9%.

Additionally, the rising trend towards advanced materials, particularly in the realm of high-density interconnect (HDI) boards and flexible PCBs, is transforming traditional manufacturing processes. The market for photosensitive polyimide (PSPI) is set to grow significantly, with projections estimating it will reach $35.875 billion by 2033, marking a notable CAGR of 27.5% from its 2025 valuation of $51.37 billion. This growth can be attributed to the increased application of PSPI materials in high-performance electronics, further highlighting the pivotal role that advanced circuit board technologies play in driving innovation across multiple sectors.

Innovation in PCB Fabrication: Meeting the Demands of IoT and Smart Devices

In the rapidly evolving landscape of technology, the demand for advanced printed circuit boards (PCBs) is at an all-time high, particularly driven by the surge in Internet of Things (IoT) devices and smart technologies. The innovation in PCB fabrication is crucial for meeting the unique requirements of these applications. Manufacturers are now focusing on creating highly efficient, compact, and reliable circuit boards that can support the complex functionalities of smart devices. This entails utilizing cutting-edge materials and techniques that not only enhance performance but also reduce production costs.

Moreover, the integration of smart technology into everyday items emphasizes the need for flexibility in PCB design. Customization, scalability, and rapid prototyping are essential features that modern PCB fabrication processes must offer. By embracing innovative fabrication techniques such as multi-layer construction, advanced etching, and additive manufacturing, companies can better align their products with the intricacies of IoT frameworks. This adaptability allows for quicker response times to market demands and ensures that products are equipped to handle the data-heavy and interconnected nature of today's digital world.

Cost Efficiency and Quality: Balancing Trade-offs in Circuit Board Production

In the competitive landscape of electronics manufacturing, balancing cost efficiency and quality in circuit board production is crucial for businesses aiming to thrive. The intricate process of circuit board fabrication often presents a dilemma: while cutting costs can streamline production, it may inadvertently compromise the quality and reliability of the end product. This trade-off requires manufacturers to adopt a strategic approach to ensure they achieve a favorable balance.

Investing in high-quality materials and advanced fabrication techniques can lead to a more durable and reliable circuit board, ultimately enhancing product performance. However, these investments may drive up initial production costs. To offset this, manufacturers can consider bulk ordering components or optimizing their production processes to reduce waste. By carefully analyzing their operational strategies and employing smart procurement practices, companies can maintain quality standards while achieving significant cost savings, thereby fostering long-term growth and customer satisfaction in a diverse range of product applications.